Applied Engineering, Turnkey Projects

- Equipment Reinstallation

- New Equipment Installation

- Anchor Bolt Replacement and Removal

- Grouting

- Structural Repairs and Reinforcements

- Technical Analyses

Specialized in the application of polymer technologies and bearing-alignment devices for upgrading damping systems and the installation/reinstallation of heavy machinery and static equipment.

Your strategic partner for foundation issues, providing highly specialized engineering services for both static and dynamic reliability challenges. Our expertise includes foundation and equipment installation and reinstallation

With a skilled workforce ready to mobilize quickly across Europe, the Middle East, and North Africa, we ensure prompt and efficient project execution.

Key Features:

- Committed to dynamic reliability and preventing breakdowns

- We correct and restore the structural strength of the foundations

- Optimal efficiency for the absorption and transmission of the mechanical energy exerted by the machine

- Lifetime Service Guarantee: We stand behind our work with a lifetime warranty, ensuring the longevity and durability of our solutions

- Turnkey Projects: From initial assessment to final implementation, we offer comprehensive turnkey solutions tailored to your specific needs.

We repair and upgrade the entire damping system

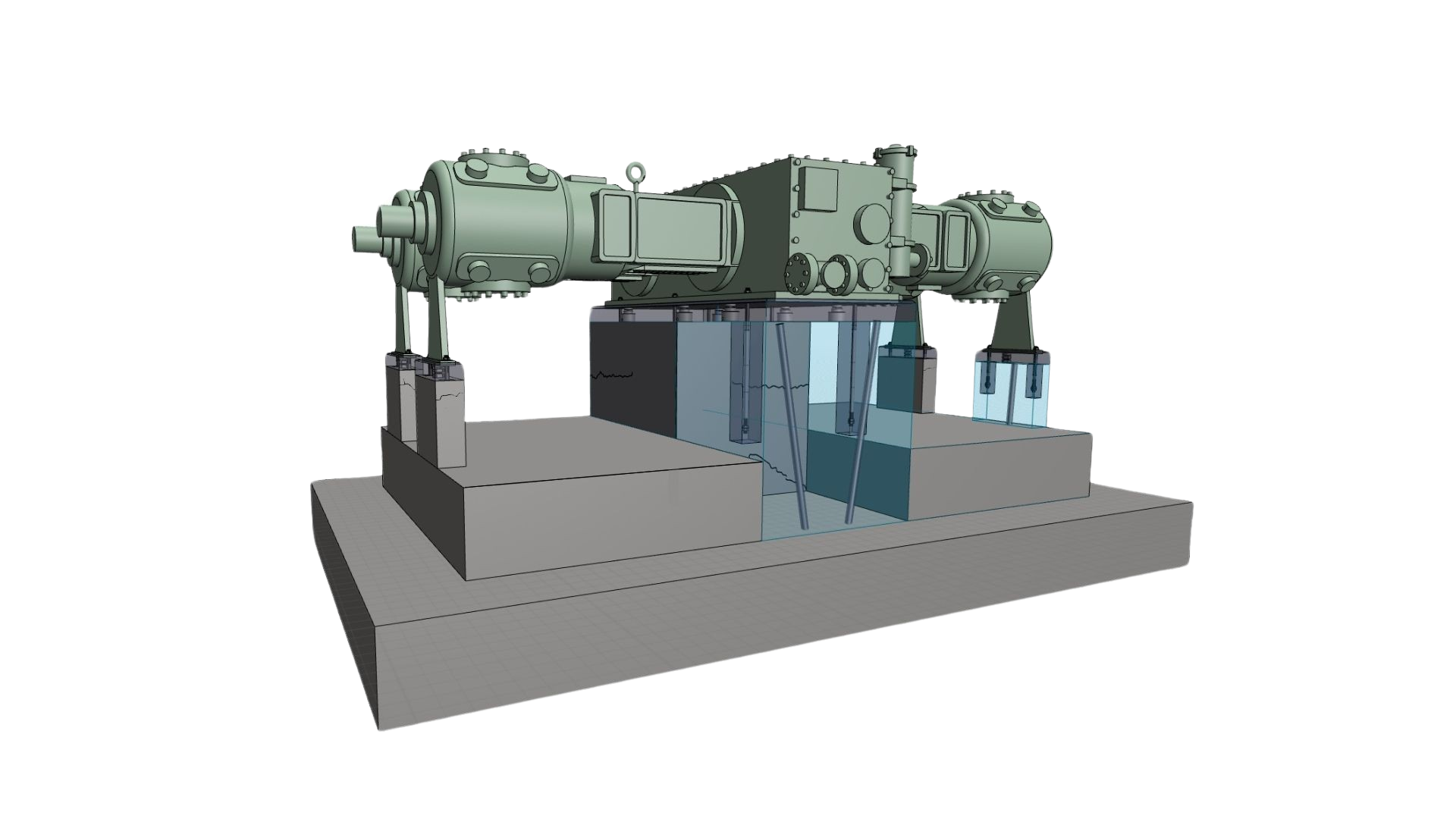

We repair and upgrade the entire damping system, from the bed frame to the subsoil, tackling foundations issues on both approaches: Dynamic and statically. We strengthen and restore your installation components through different techniques: consolidations, injections, regrouting (machinery off-site or on-site), anchor bolt repair and replacement, subsoil stabilization, and enlargement and modifications of forms.

Our expertise covers a wide range of equipment, including: Compressors and Hypercompressors, Engines and Pumps, Diesel Engines and Tanks, Cooling Towers and Blowers, Generators and Turbines, Roller Benches and Test Stands, Gearboxes and Dryers, And more…

The structural flaws of the damping system and the machine installation condition are inferred through more or less evident symptoms. These symptoms not always are easily translatable in causes; for that reason, the essence of each technical report will consist of evaluating the dynamic response of its installation elements: grout, anchoring system and foundation blocks

Technical Analyses

Foundation stitching, epoxy injections, frame reinforcement, bolt repair, structural reinforcement, mass enrichment, enlargement, and shape modification.

Structural Repairs & Reinforcements

With over 200 successful projects under our belt, we specialize in grouting heavy equipment installations such as compressors, pumps, and diesel engines. Our solutions adhere to

international quality standards, guaranteeing optimal performance and longevity.

New Machinery Instalation

Benefit from over 25 years of experience in sealing and repairing pump rooms and pits. Our proven solutions ensure the protection and longevity of critical infrastructure.

Sealing & Waterproofing

Our partners and clients

Explore the countries where Apoltec has successfully executed projects

Why choose Apoltec?

Client Satisfaction

Our passion for excellence drives us to deliver superior service and materials, backed by unparalleled after-sales support.

100% client satisfaction is our ultimate goal.

Cost and Time Savings

By preventing machinery breakdowns and ensuring the longevity of equipment, we help our clients save both time and money.

Committed to Dynamic Reliability

Strengthen, rebuild, and reinforce foundations to prevent mechanical damage to equipment.

EFRC GUIDELINES

Apoltec adheres to the European Forum Reciprocating Compressors (EFRC) guidelines, embodying international standards and best practices for foundations, anchor bolts, and grouting of reciprocating compressor systems.

We are committed to delivering exceptional results for every project, dedicating the time and expertise required to exceed client expectations.

Company committed

to safety

Apoltec is committed to safety, with a zero-accident record and a dedicated safety plan for every project