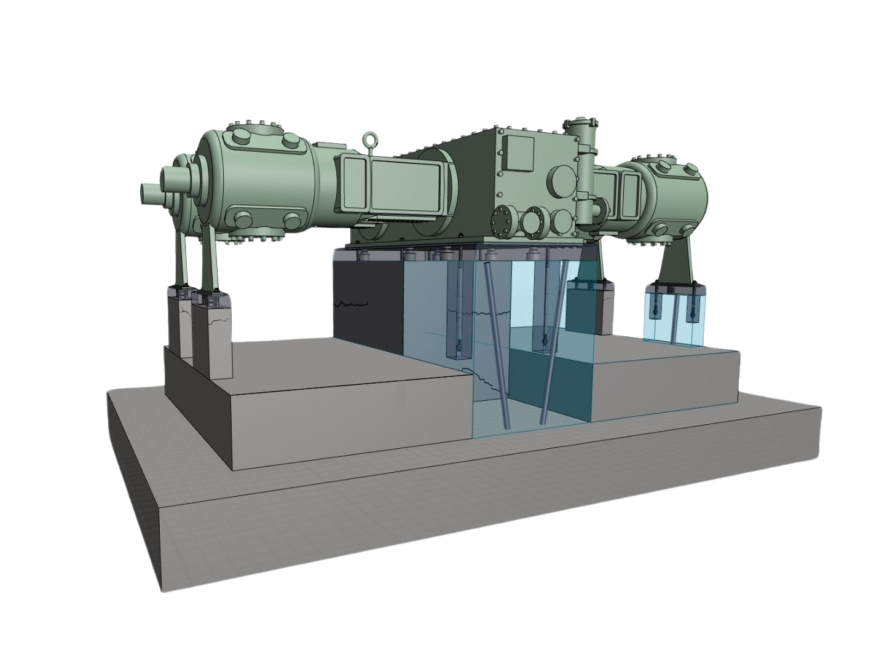

We repair and upgrade the entire damping system, from the bed frame to the subsoil, tackling foundations issues on both approaches: Dynamic and statically. We strengthen and restore your installation components through different techniques: consolidations, injections, regrouting (machinery off-site or on-site), anchor bolt repair and replacement, subsoil stabilization, and enlargement and modifications of forms.

Our expertise covers a wide range of equipment, including: Compressors and Hypercompressors, Engines and Pumps, Diesel Engines and Tanks, Cooling Towers and Blowers, Generators and Turbines, Roller Benches and Test Stands, Gearboxes and Dryers, And more…

The structural flaws of the damping system and the machine installation condition are inferred through more or less evident symptoms. These symptoms not always are easily translatable in causes; for that reason, the essence of each technical report will consist of evaluating the dynamic response of its installation elements: grout, anchoring system and foundation blocks

Foundation stitching, epoxy injections, frame reinforcement, bolt repair, structural reinforcement, mass enrichment, enlargement, and shape modification.

With over 200 successful projects under our belt, we specialize in grouting heavy equipment installations such as compressors, pumps, and diesel engines. Our solutions adhere to

international quality standards, guaranteeing optimal performance and longevity.

Benefit from over 25 years of experience in sealing and repairing pump rooms and pits. Our proven solutions ensure the protection and longevity of critical infrastructure.