Dynamic Foundation Engineering

Our interventions achieve the restoration of dynamic stability

We ensure mechanical reliability, preventing breakdowns, and increasing equipment lifespan, operational efficiency, and safety.

Our solutions are meticulously designed to deliver cost and time savings for our clients, ensuring optimal performance and longevity of their equipment.

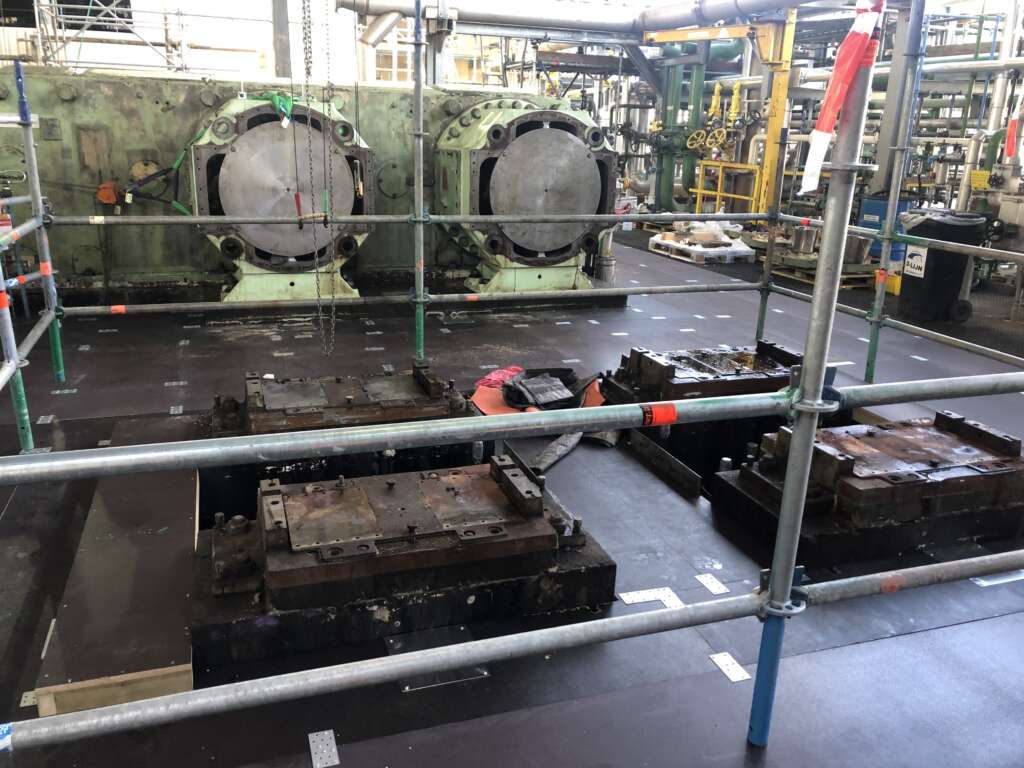

With a focus on dynamic equipment, on-site repairs, and our proprietary epoxy grout, we have successfully completed over 4,000 projects for leading companies in sectors such as Petrochemicals, Refining, Steel, and Fertilizers.

Our extensive experience encompasses a wide range of machinery, including compressors, hypercompressors, diesel engines, electric motors, pumps, reducers, blowers, turbines... Ultimately, we can and have experience in repairing and enhancing the foundations of any dynamic or static equipment

Irrespective of the base material, whether it's metal plates, racks, or direct foundation applications, Apoltec offers tailored strategies that comply with international regulations, setting industry standards.

There are several symptoms revealing an incipient damping system fatigue, for instance:

Cracks induced by thermal and mechanical stress.

Oil penetration that counteracts friction response against lateral movement or detaches grout from machine footprint, anchor bolts or foundation.

Corrosion of peripheral rebar, anchor bolts or bed frame surfaces that affects alignment and vibration isolation response.

Cold or construction joints separation that discontinues foundations as a continuous mass behaving as undersized dampener.

Shear stress on anchor bolts or loss of stretching and torque.

Air gaps underneath mounting frames where oil can be drawn in or to allow resonance

Subsoil differential settlement which may increase rocking movement.

Our approach

Our comprehensive approach encompasses the entire project lifecycle, from meticulous technical analysis to precise execution. Whether it’s dynamic or static machinery, we ensure optimal performance and longevity, adhering to the highest international standards as API686, EFRC, ASCE, ACI, ISO, ASTM. BSI, EHE…

In the event of a stability issue arising from degraded grout due to oil and vibration, Apoltec offers a solution to replace the existing grout without the need to remove the equipment, saving time and complications for the end-user.

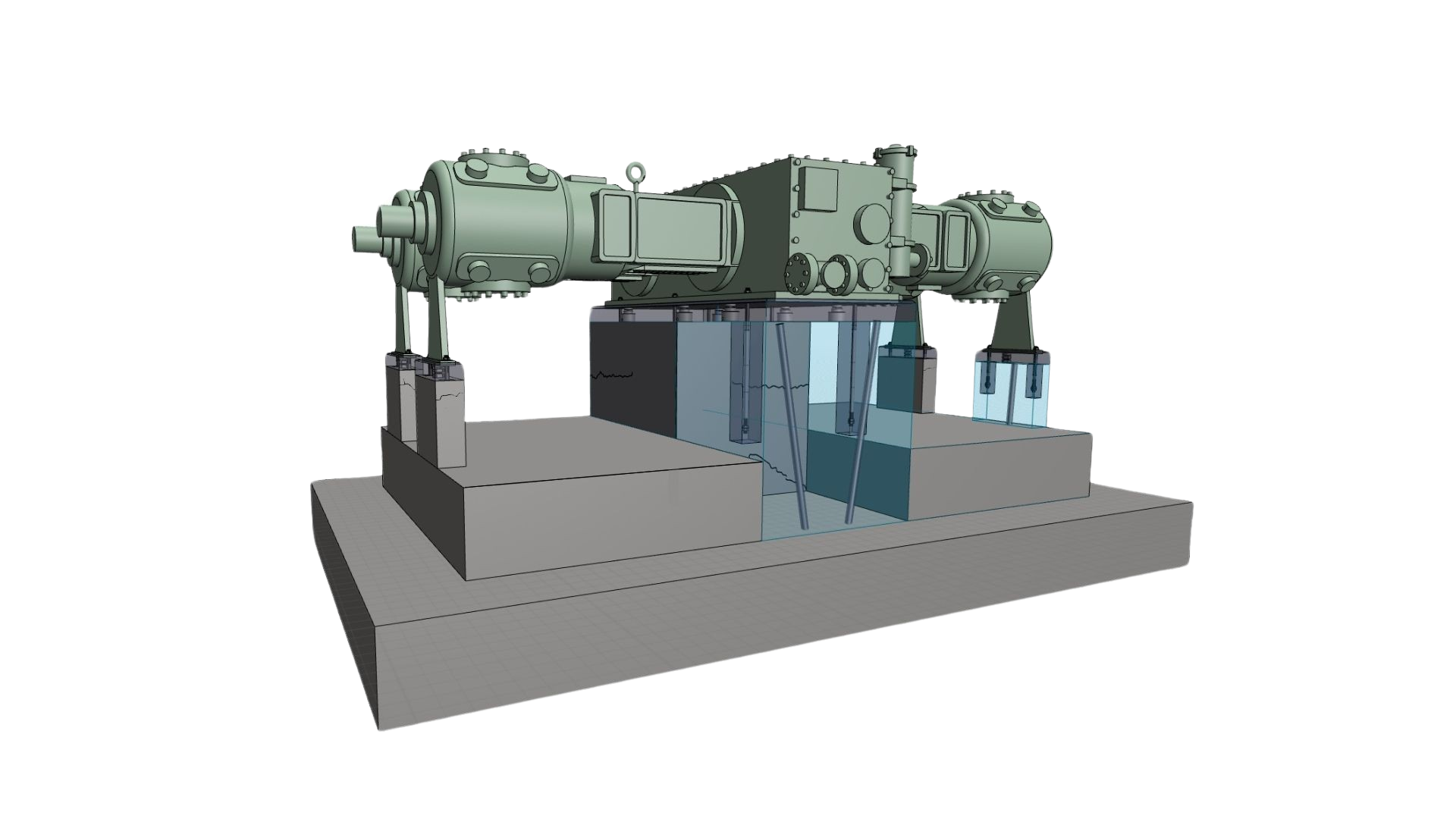

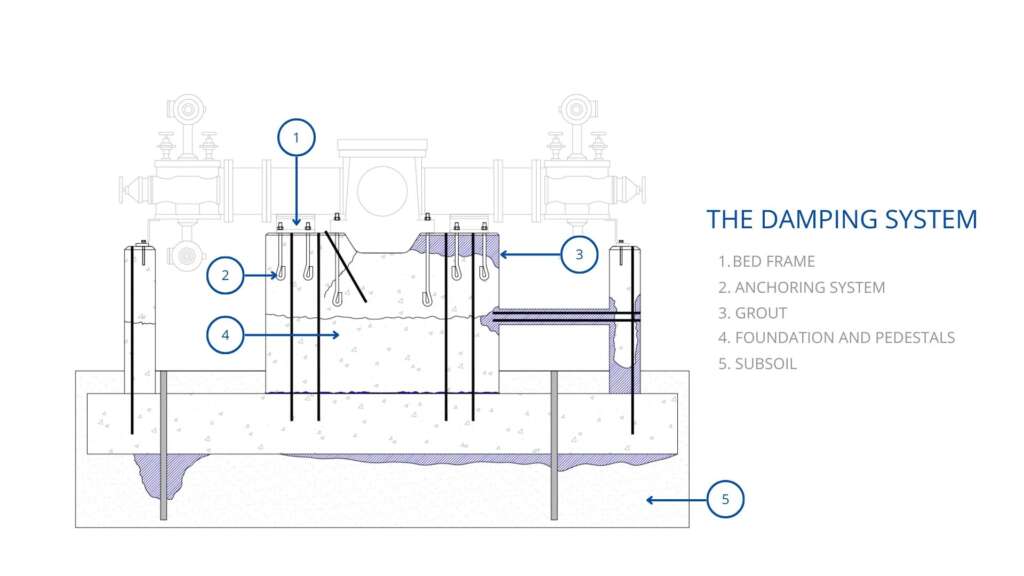

About the damping system, is essential to effectively absorb and attenuate the residual mechanical energy of the machine, transferring it to the subsoil in the form of a natural spring.

Our specialty is optimizing the damping system, from the bed frame to the subsoil, eliminating unwanted vibrations, repetitive misalignments, poorly grouted areas, corrosion, damaged bolts… In essence, the restauration of dynamic foundations damping ability that have a direct impact on the equipment.

A standard damping system comprehends:

- Base Frame, which is consider the highest rigid structure being part of the machine case or not (mounting frame, skid, sole plates, rails, …). It’s hold down to the foundation thru the anchoring system.

- Anchoring system performs as device for displacement restrain and is critical for modifying the tensional state of underlying materials in order to better resist fatigue.

- Grout is a layer that connects machine to the main foundation inertia block and has an essential damping and inertia restrain duty.

- Foundation, in the way of mat or slab, base rafts, columns, pillars, plinths, inertia blocks, and so on, lowers gravity center, increases and adds inertia mass to the machine, dampers vibrations, and compress under pressure subsoil materials.

- Subsoil, as a natural spring for energy dissipation. It is tuned on phase by all elements above.

EQUIPMENT FOUNDATION REPAIR PROCESS

1. Technical Analysis and Inspection

We conduct a thorough physical assessment and analysis to prepare the technical project and security plan.

2. Product Design and Selection

Based on climatic and chemical factors, we select the most suitable Apoltec products to achieve project goals.

3. Design and Manufacture of Support Frames

Our engineering team designs and manufactures frames to support machinery if necessary.

4. Demolition of Equipment Foundation

We remove the surface of the original base and re-foundation unrecoverable points.

5. Epoxy Injection and Crack Repairs

Utilizing our Apoltec 370 resin, we perform highpressure injection to consolidate the bench and extract filtered residues, ensuring adhesion on oil-contaminated surfaces.

6. Anchor Bolt Removal and Replacement

Apoltec offers solutions for anchor bolt breakage, providing design and installation services for anchor bolts of all sizes.

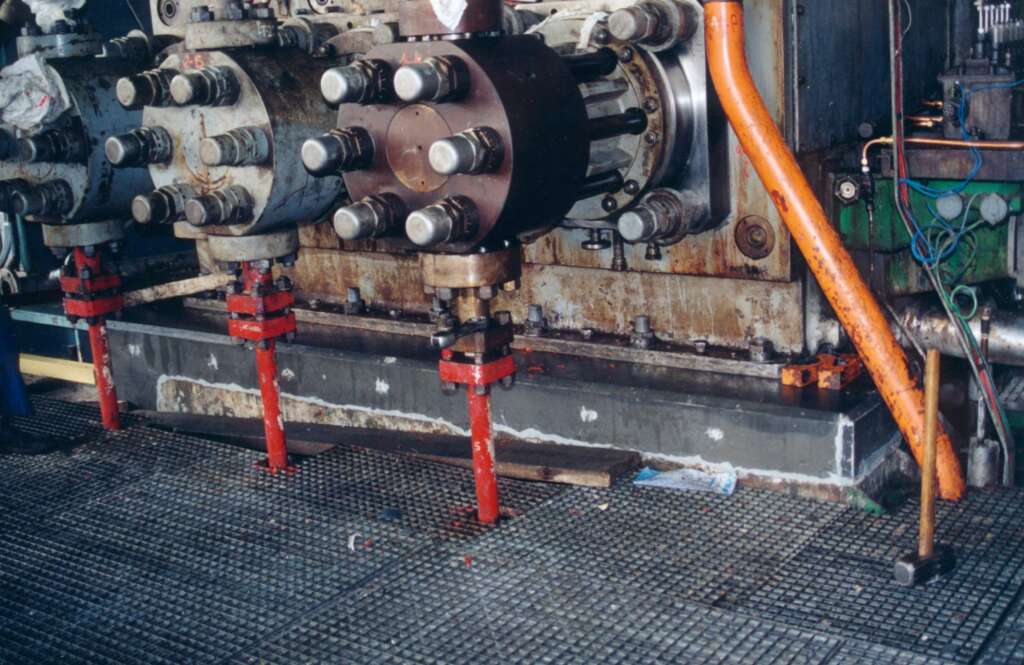

7. Hydraulic Pad Lift

We utilize hydraulic pads to sustain machinery and facilitate leveling, avoiding "hard spots."

8. Machine Leveling

Our team analyzes and corrects any deviations of the machine with respect to alignment points using dial gauges and meters.

9. Formwork Design and Manufacturing

We design and manufacture formwork according to grouting location and requirements.

10. Machine Grouting

With over 25 years of experience, we expertly grout heavy machinery, selecting the best method based on equipment placement and frame.

Some of our projects

technical information

1. Damping Sytem

A damping system efficiently absorbs and attenuates residual mechanical energy from the machine, transferring it to the subsoil as natural spring.

A standard damping system comprehends:

Frame, which is consider the highest rigid structure being part of the machine case or not (mounting frame, skid, sole plates, rails, …). It’s hold down to the foundation thru the anchoring system.

Anchoring system, performs as device for displacement restrain and is critical for modifying the tensional state of underlying materials in order to better resist fatigue.

Grout, is a layer that connects machine to the main foundation inertia block and has an essential damping and inertia restrain duty.

Foundation, in the way of mat or slab, base rafts, columns, pillars, plinths, inertia blocks, and so on, lowers gravity centre, increases and adds inertia mass to the machine, dampers vibrations, and compress under pressure subsoil materials.

Subsoil, as a natural spring for energy dissipation. It is tuned on phase by all elements above.

2. Dynamic Stability

Achieving dynamic stability ensures mechanical reliability, preventing breakdowns and increasing equipment lifespan, operational efficiency, and safety.

3. Know How

We specialize in integral dampening system reconditioning, considering it as a monolithic mass connected to the machine.

Our expertise lies in diagnosing symptoms, identifying causes, designing solutions, executing repairs, and conducting regular inspections.

4. Mechanical Adjustments

Proper machinery installation involves precise leveling, alignment, and adjustment of equipment bodies to prevent stress concentration and ensure long-term stability.

5. Phases Covered by Apoltec

We cover the entire project from problem detection to engineering and execution, offering turnkey solutions with a skilled team and advanced technology.

6. Type Of Machinery Experience

Specializing in dynamic equipment and on-site machinery repairs, we also have extensive experience with static machinery repairs, backed by over 25 years of expertise.

7. Importance of Repairs by Foundation Specialists

Combining mechanical requirements with equipment design and concrete forms requires expertise. Apoltec simplifies procedures and adjusts investment resources, ensuring meticulous repairs with professional teams and advanced technology.

At Apoltec, we prioritize excellence in every project, delivering exceptional results with precision and efficiency.